"Virtualization, applied to the context of industrial automation, translates into process precision, optimization and reliability, subject to validation with the customer."

Photo courtesy of: Avantek Solutions.

GURPEA GROUP Acquires Tecnomatix Process Simulate.

In a commitment to efficiency and excellence in industrial automation, GURPEA GROUP has taken a significant step by acquiring the license of Tecnomatix Process Simulate, a leading software in simulation and machine-robot interaction, designed for projects with a high degree of automation, to which only large-scale companies have access due to its cost and the investment in training of the required team.

Therefore, this strategic step not only positions GURPEA GROUP as a pioneer in the adoption of advanced technologies that strengthen its position in the market, but also reflects its commitment to the reliable delivery of automation projects.

What is Tecnomatix Process Simulate?

Tecnomatix Process Simulate is a powerful digital production solution designed for process verification in a 3D environment. This tool stands out as a time-to-market driver by enabling virtual validation of manufacturing concepts, shortening project delivery times, reducing errors and improving final product quality.

The increasing complexity of products and manufacturing processes presents significant time-to-market challenges. Process Simulate becomes an essential tool by enabling the planning, simulation and validation of human tasks, robotics and automation processes throughout the entire product development lifecycle, from conceptualization and engineering to production and continuous improvement.

"Virtualization, applied to the context of industrial automation, translates into precision, optimization and reliability of processes, after validation with the customer." - Rubén Villanueva, Head of Technical Office at GURPEA GROUP.

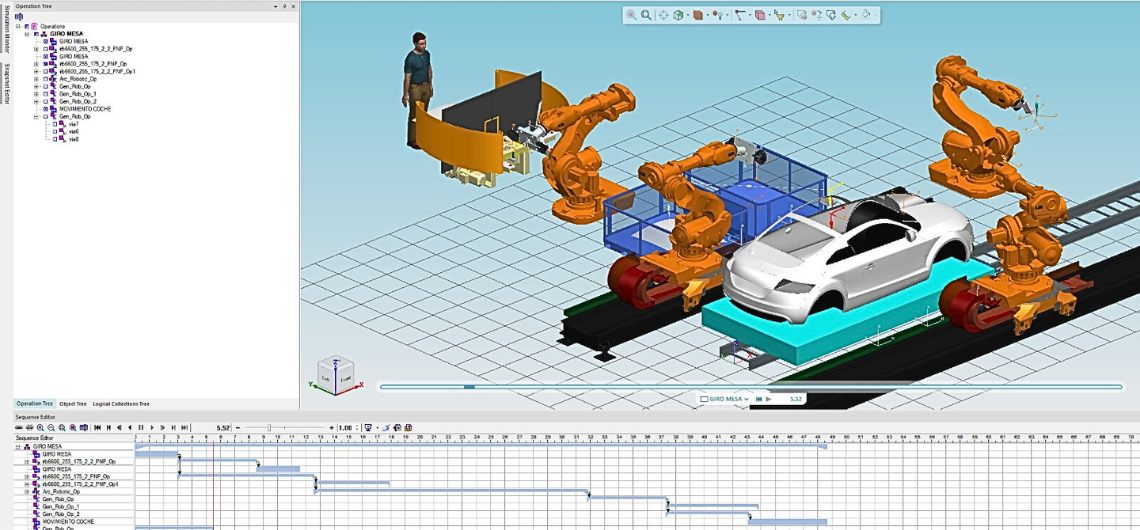

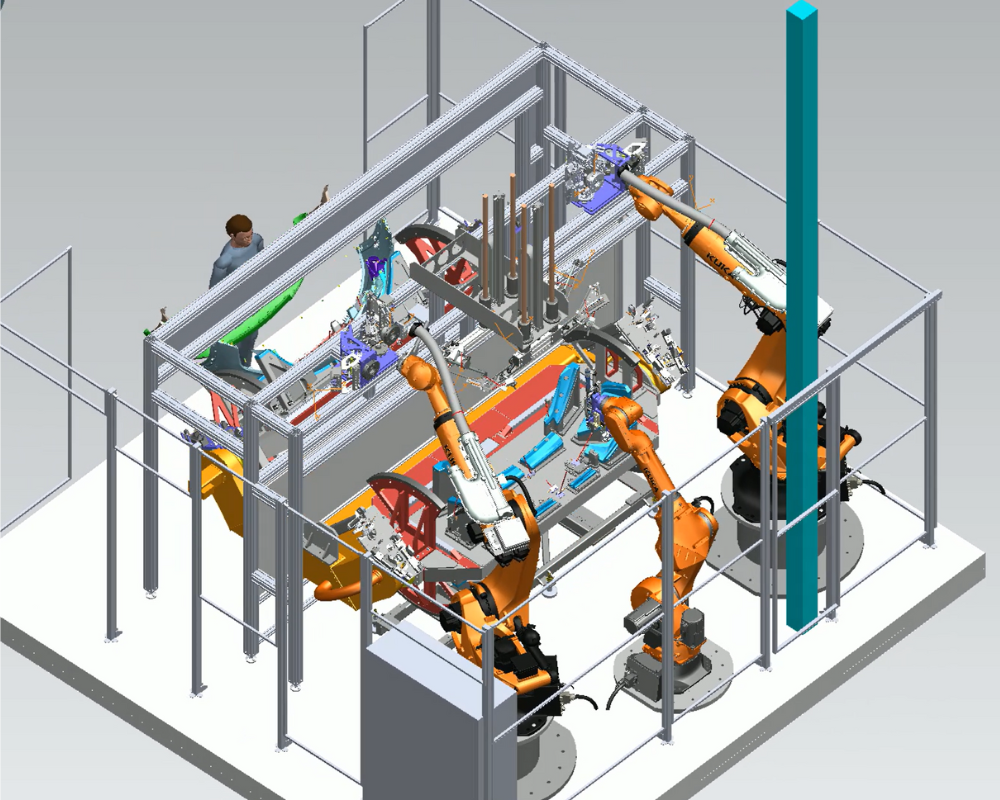

Process Simulate provides an advanced 3D environment capable of emulating the actual behavior of production processes and optimizing cycle time and process sequence. It facilitates the simulation of assembly processes, human operations and mechanical procedures of tools, fixtures and robots. This realistic emulation capability is essential to overcome successful start-up and position yourself in an increasingly competitive market.

Photo: Virtual simulation of Gurpea's project, with Process Simulate

Key functionalities.

Process Simulate's many features include the calculation of ranges, trajectories and cycle times, as well as the ability to perform collision avoidance studies. The ability to test projects in a virtual environment, known as a "digital twin," allows teams to move through the customer handover and commissioning phases with greater reliability and likelihood of success.

On the other hand, the link between programming and design is one of the biggest challenges in the life cycle of an automation project. With Tecnomatix Process Simulate, GURPEA GROUP companies will ensure good results in this area, and will strengthen their competitiveness in the market.

That is why the use of Tecnomatix Process Simulate translates into new product launches without failures and aligned with crucial objectives such as cost, quality and start of production, thanks to the virtual validation of processes in advance in virtual environments.

Process Simulate benefits:

Avantek Solutions, a Siemens partner company, was in charge of training the GURPEA GROUP team about the software and the advantages offered by its implementation for automation engineering processes, among which are:

-

Reduce costs with early detection.

Detect and communicate product design problems early, reducing costs associated with late changes.

- Fewer physical prototypes.

Virtualizes early validation, reducing the need for multiple physical prototypes.

- Optimized cycle times.

Simulates and optimizes cycle times for more efficient production.

- Ergonomically safe processes.

Ensures ergonomic processes, prioritizing operator safety and well-being.

- Reuse of standard tools.

Reduces costs by reusing standard tools and facilities.

- Minimization of production risks.

Mitigates risks by simulating various production scenarios prior to physical implementation.

- Early validation of integrated processes.

Early validation of mechanical and electrical processes, including PLC and robotics.

- Virtual Commissioning.

Performs early validation of production commissioning in a virtual environment.

- Continuous Quality Improvement.

Increases process quality by emulating real processes throughout the entire process life cycle.