Challenges of industrial maintenance today.

"Invertir en un servicio de contratación propio, la formación especializada y continua de nuestros técnicos, y poner a nuestro personal siempre en el centro, nos otorga una posición diferencial en el entorno tan competitivo en el que trabajamos” - explica Álvaro Pajares, Director de Operaciones de Gurpea -.

The contemporary industrial world is facing a challenging time in the field of maintenance. As advanced technologies and operations become more complex, industrial maintenance professionals are at the crossroads of adapting to changing market demands for more and more data, control and process optimization.

1. Emerging Technologies.

The accelerated advancement of technology, such as the Internet of Things (IoT), artificial intelligence (AI) and machine learning, has revolutionized industrial operations. While these technologies offer significant opportunities to improve efficiency and predictability, they also pose challenges in terms of staff integration and training. Maintenance teams must constantly update themselves to take full advantage of these innovations and ensure their effective application in the industrial environment.

2. Predictive Maintenance.

While predictive maintenance has proven to be a valuable strategy for avoiding unplanned failures, its implementation continues to present complexities in terms of accessing and analyzing large amounts of data. Effective management of the enormous amount of information generated by sensors and monitoring systems requires robust systems and personnel skilled in analytics, a scarce resource in many industrial environments.

3. Skills Shortage.

In addition, the rapid evolution of industrial technologies has created a skills gap in the maintenance sector. The lack of professionals trained to handle sophisticated equipment and adopt new technologies is a recurring challenge. Companies are faced with the task of attracting, retaining and training qualified personnel to ensure efficient maintenance operations.

Picture: Álvaro Pajares, Gurpea's Operations Director

In this sense, Gurpea has been incorporating improvement actions for some time to position itself as a competitive alternative in the sector:

"Investing in our own recruitment service, the specialized and continuous training of our technicians, and putting our staff always at the center, gives us a differential position in the highly competitive environment in which we work" - explains Álvaro Pajares, Gurpea's Operations Director -.

4. Regulatory Compliance.

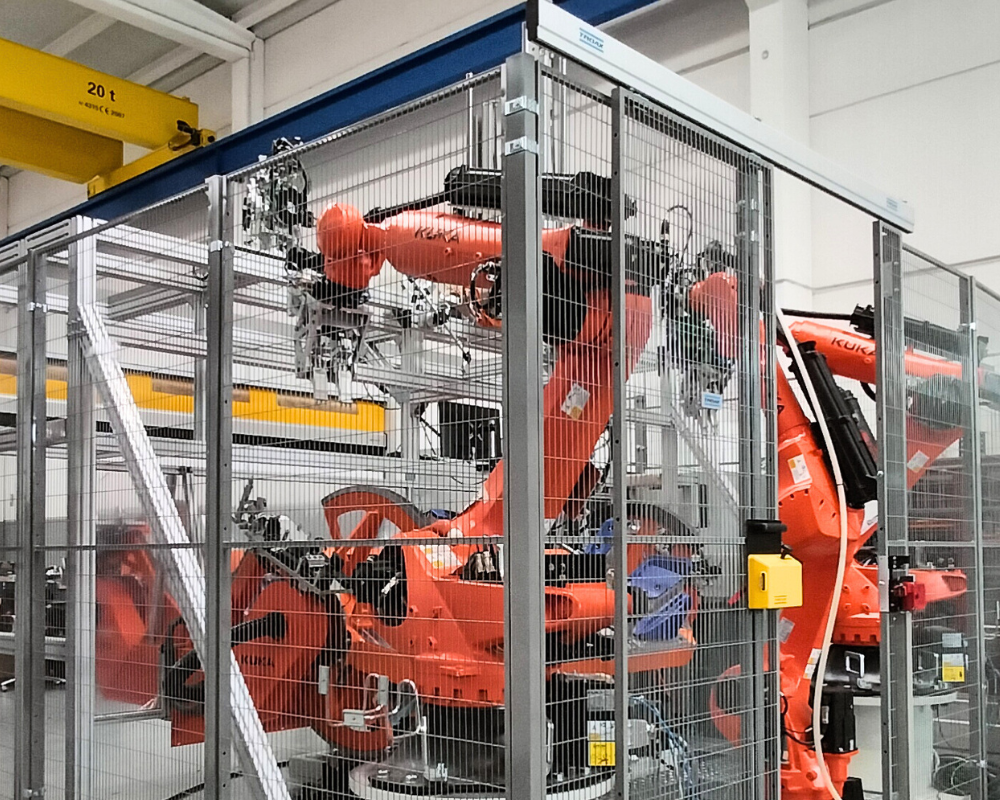

Industrial maintenance teams also face increasingly stringent regulatory compliance. Companies are placing increasing emphasis on the safety of their production facilities, and the transition to safer practices often involves the adaptation of equipment and processes, with investment in engineering, materials, materials and equipment.

The transition to safer practices often involves the adaptation of equipment and processes, with the investment in engineering, materials and assembly that this entails.

A clear example of this is that in Gurpea we have seen increased demand from our customers to adapt to Royal Decree 1215, in 2023. Invoicing in adaptations and certifications has doubled compared to the previous year,

Picture: perimeter protection with interlocking closure.

5. Asset Management with an integrated approach.

The increase in the complexity of operations and the search for greater optimization leads to an increasingly precise and coordinated management of critical assets. The need for strategic planning and a comprehensive approach in this field, which avoids costly downtime and loss of productivity, is now inherent to any industrial maintenance project. A task that, due to the knowledge, experience and time it requires, tends to be outsourced by industrial companies.

Against this backdrop, Gurpea will continue to focus its efforts on offering proximity to customers in order to detect the evolution of their needs and continue developing services and technologies that guarantee maximum efficiency and optimization of their lines.